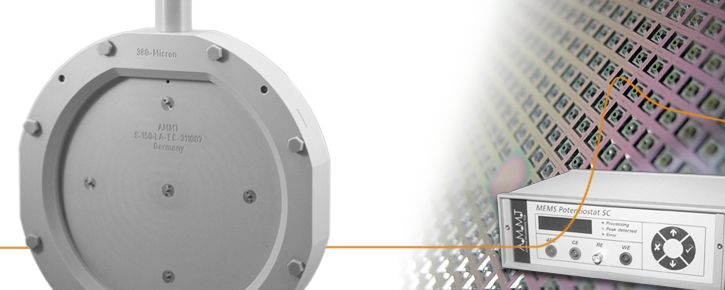

Wafer Holders with electrical contacts and dedicated potentiostats

Model MC – a flexible solution from lab to industry.

While our MEMS Potentiostat Model SC primarily focuses on research and development purposes, AMMT also offers a solution for small to large scale production of MEMS devices. Our multi-channel potentiostat Model MC incorporates four, eight, 12 or 16 independent potentiostatic systems. As each sub-system is fully electrically insulated, up to 16 wafers can be etched simultaneously and independently in the same anisotropic etching bath. An optimum utilization of your KOH- or TMAH-equipment is thereby assured while saving your company's financial and personal resources.

Designed as an industry standard 19"-rack, the Model MC smoothly integrates into an existing clean-room environment. Setting up the system is easy, as each potentiostat unit has its own hybrid connector that holds all necessary signal and power lines for the respective etch chuck.

Our graphical control software package MPC is included with the Model MC potentiostat as an adapted multi-channel version. This program not only controls up to 16 potentiostats, it also offers a production oriented software front-end for the etch-stop operator.

AMMT also delivers the Model MC potentiostat integrated into any automated wet bench.

For more information, please download our product info below.

For a complete list of our product information sheets please see our Documentation Download Section.